Gridraster

In the realm of XR and 3D modeling, the challenge has been the slow and costly process of creating digital twins using traditional methods. Industries have been hindered by the need for exotic scanning equipment, which not only slows down the creation process but also drives up costs.

Enter GridRaster Digital Twin, a game-changing solution that transforms this landscape. By leveraging commercial equipment, GridRaster accelerates the scanning and creation of 3D digital twins. This innovation enables content creation at unprecedented speeds—ten times faster than before—and at a fraction of the cost. The platform’s advanced XR model creation algorithm ensures millimeter precision, which is crucial for accurate simulations, defect detection, and analysis. It also supports models with significantly more polygons, handling complex scans with ease.

GridRaster’s technology empowers industries to manage their assets more effectively. With real-time sensor data streaming and precise localization, mapping, and visualization capabilities, industries can now monitor asset conditions throughout their lifecycle, optimize maintenance, and respond rapidly to defects. In summary, GridRaster Digital Twin addresses the inefficiencies in traditional XR/3D modeling by providing a faster, cost-effective, and precise solution, setting a new standard for the industry.

Industries that require precise 3D scanning and model generation for various applications. This includes sectors that benefit from digital twin technology for tasks such as simulation, defect detection, analysis, maintenance operations, and asset management.

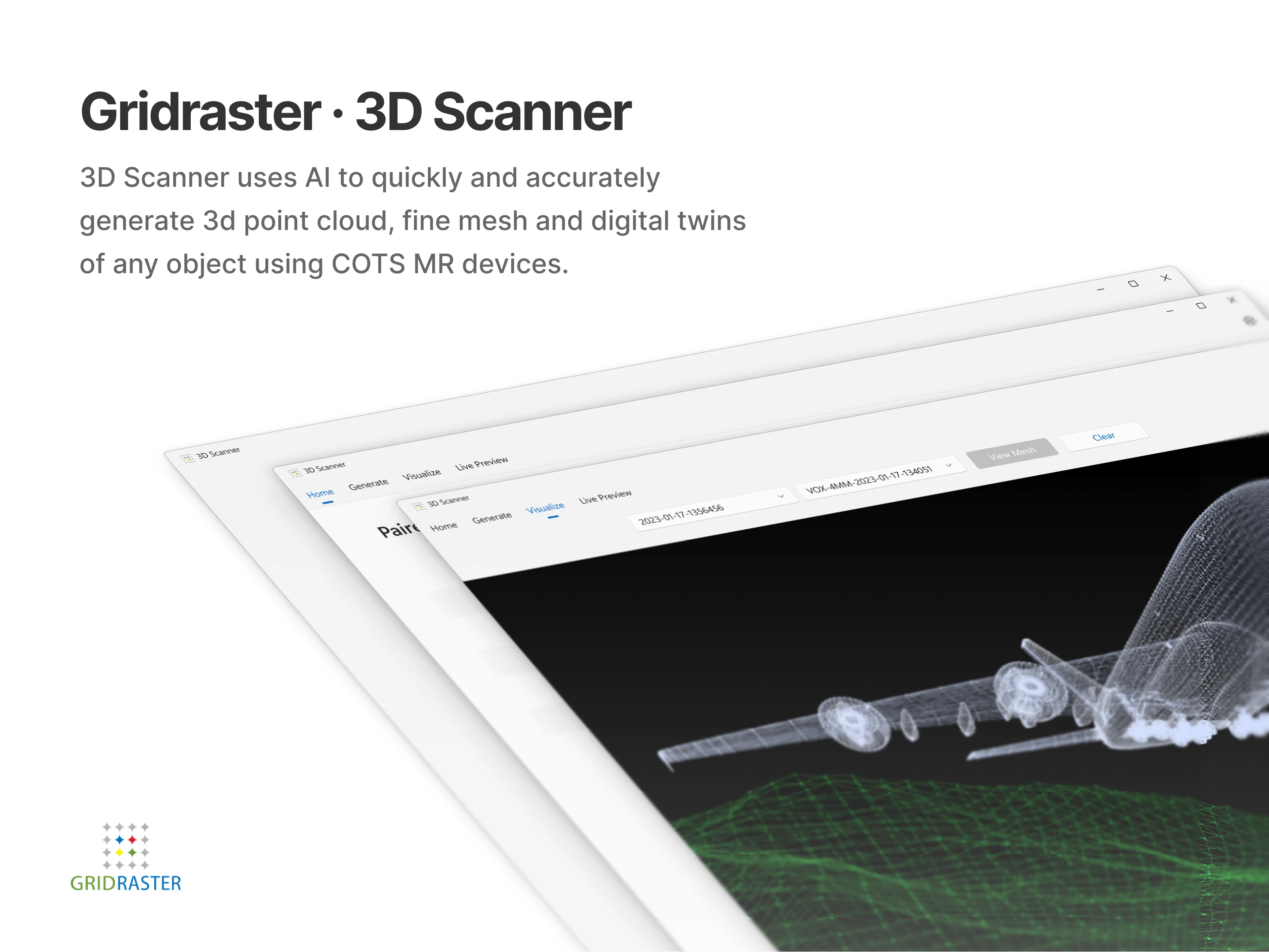

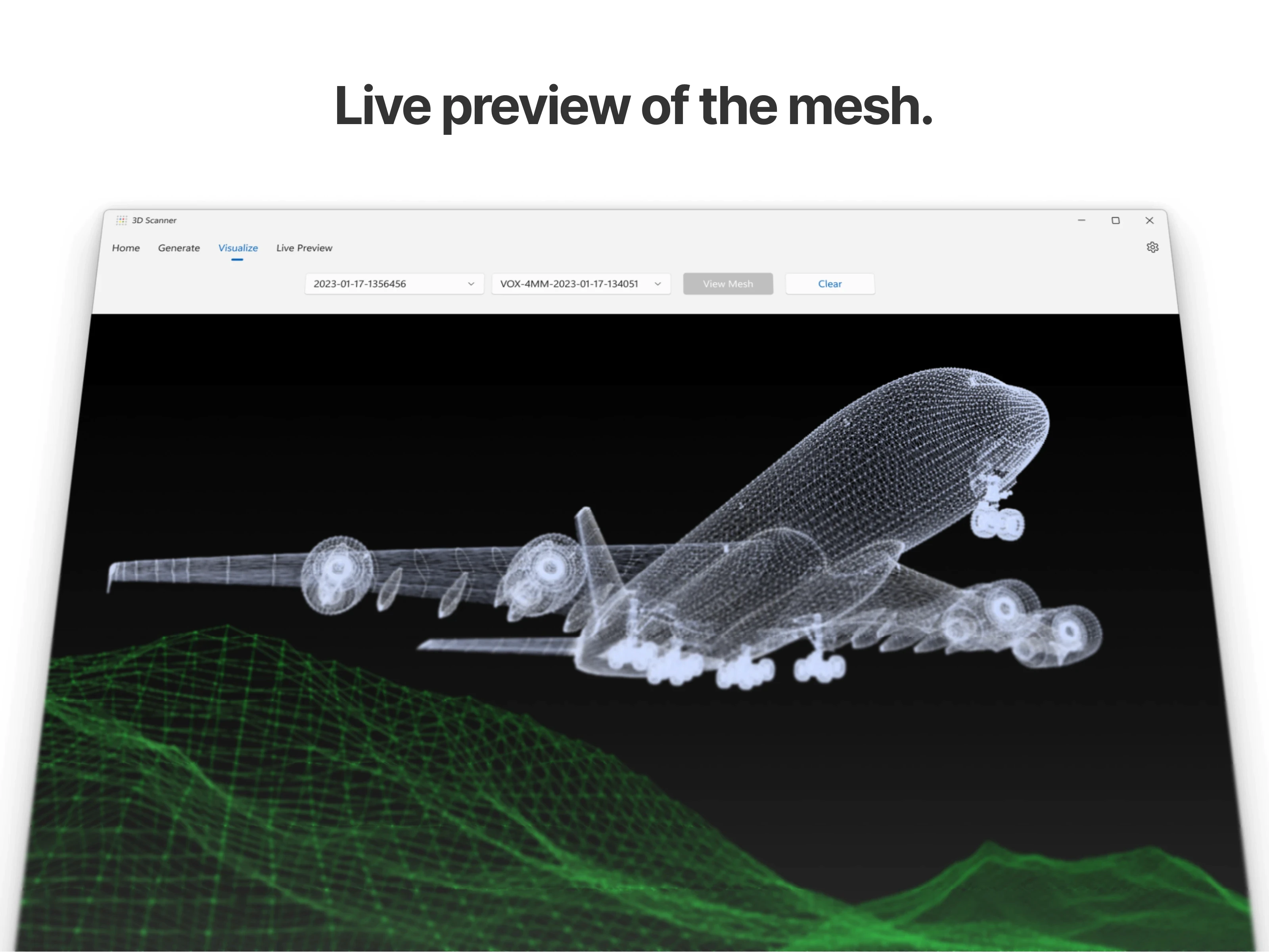

They wanted to design a new desktop app for their new service Digital Twin which used AI to quickly and accurately generate 3d point cloud, fine mesh and digital twins of any object using COTS MR devices

This project was a "zero to one" initiative, starting from the initial requirements and advancing to the development of preliminary user flows during the first phase. Our emphasis was on establishing a solid information architecture and navigation subsequent to identifying and prioritizing the primary actions of the application. After going through two feedback cycles, we concluded the phase by honing the interfaces to achieve a high level of fidelity.

We adhered to the Windows design system to ensure the application's alignment with the desktop interface standards.

Our focus was on enhancing the application's navigability and enabling seamless mesh preview.

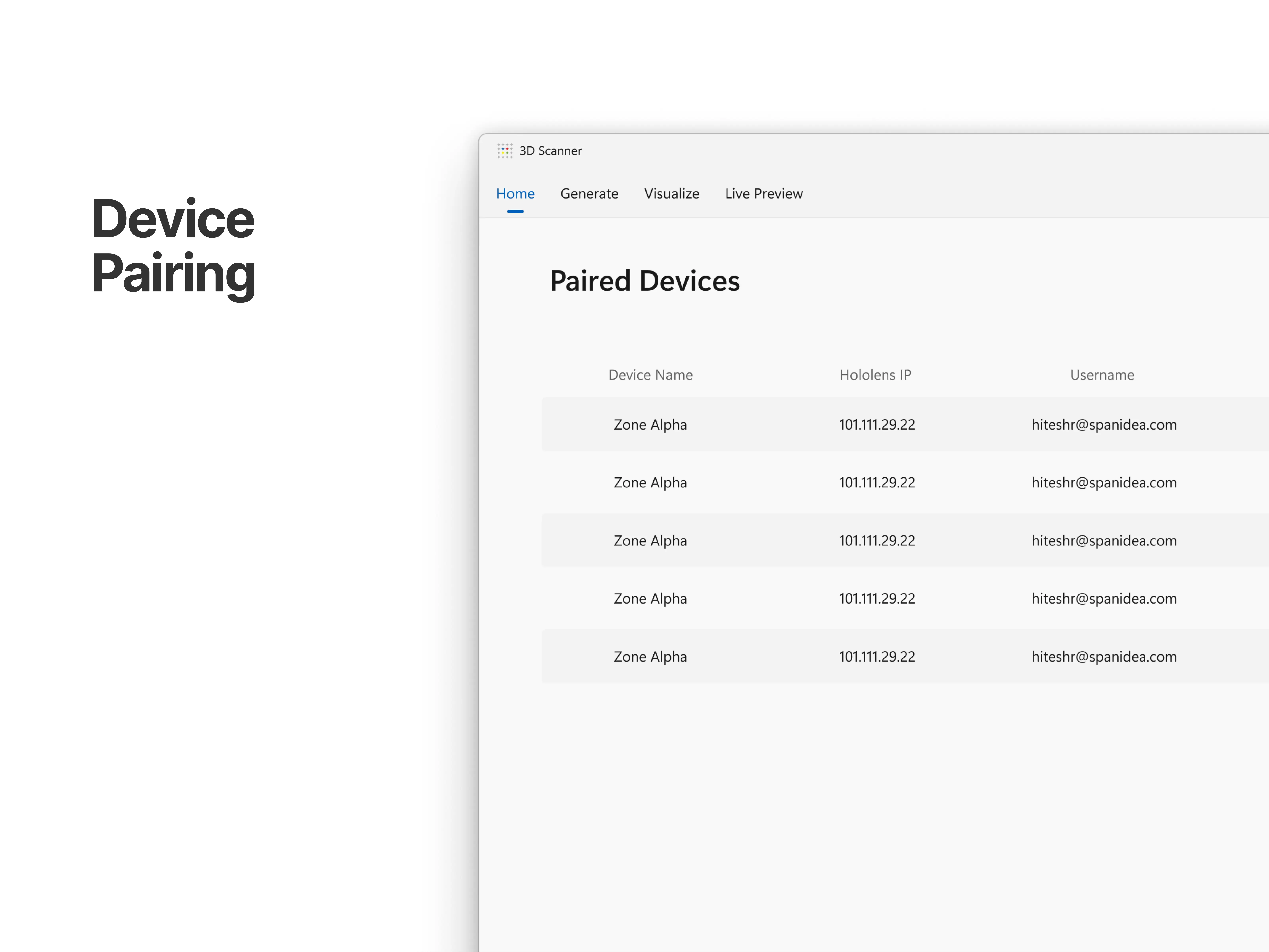

We prioritized the feasibility of the design to facilitate the pairing and storage of devices for mesh downloads.